The Blast Furnace Plant

Now that we have completed a description of the ironmaking process, let s review the physical equipment comprising the blast furnace plant.

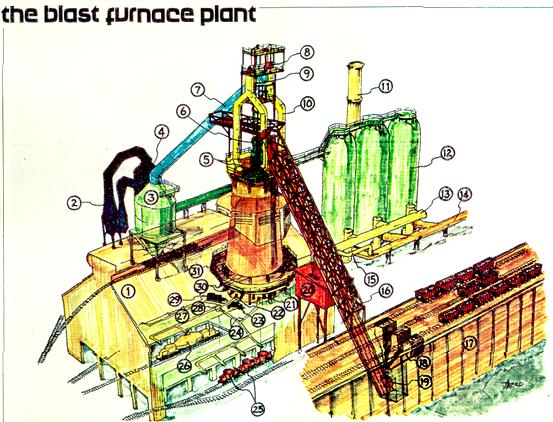

There is an ore storage yard that can also be an ore dock where boats and barges are unloaded. The raw materials stored in the ore yard are raw ore, several types of pellets, sinter, limestone or flux blend and possibly coke. These materials are transferred to the "stockhouse" (17) complex by ore bridges equipped with grab buckets or by conveyor belts. Materials can also be brought to the stockhouse in rail hoppers or transferred from ore bridges to self-propelled rail cars called "ore transfer cars". Each type of ore, pellet, sinter, coke and limestone is dumped into separate "storage bins" (18). The various raw materials are weighed according to a certain recipe designed to yield the desired hot metal and slag chemistry. This material weighing is done under the storage bins by a rail mounted scale car or computer controlled weigh hoppers that feed a conveyor belt. The weighed materials are then dumped into a "skip" car (19) which rides on rails up the "inclined skip bridge" to the "receiving hopper" (6) at the top of the furnace. The cables lifting the skip cars are powered from large winches located in the "hoist" house (20). Some modern blast furnace accomplish the same job with an automated conveyor stretching from the stockhouse to the furnace top.

At the top of the furnace the materials are held until a "charge" usually consisting of some type of metallic (ore, pellets or sinter), coke and flux (limestone) have accumulated. The precise filling order is developed by the blast furnace operators to carefully control gas flow and chemical reactions inside the furnace. The materials are charged into the blast furnace through two stages of conical "bells" (5) which seal in the gases and distribute the raw materials evenly around the circumference of the furnace "throat". Some modern furnaces do not have bells but instead have 2 or 3 airlock type hoppers that discharge raw materials onto a rotating chute which can change angles allowing more flexibility in precise material placement inside the furnace.

Also at the top of the blast furnace are four "uptakes" (10) where the hot, dirty gas exits the furnace dome. The gas flows up to where two uptakes merge into an "offtake" (9). The two offtakes then merge into the "downcomer" (7). At the extreme top of the uptakes there are "bleeder valves" (8) which may release gas and protect the top of the furnace from sudden gas pressure surges. The gas descends in the downcomer to the "dustcatcher", where coarse particles settle out, accumulate and are dumped into a railroad car or truck for disposal. The gas then flows through a "Venturi Scrubber" (4) which removes the finer particles and finally into a "gas cooler" (2) where water sprays reduce the temperature of the hot but clean gas. Some modern furnaces are equipped with a combined scrubber and cooling unit. The cleaned and cooled gas is now ready for burning.

The clean gas pipeline is directed to the hot blast "stove" (12). There are usually 3 or 4 cylindrical shaped stoves in a line adjacent to the blast furnace. The gas is burned in the bottom of a stove and the heat rises and transfers to refractory brick inside the stove. The products of combustion flow through passages in these bricks, out of the stove into a high "stack" (11) which is shared by all of the stove.

Large volumes of air, from 80,000 ft3/min to 230,000 ft3/min, are generated from a turbo blower and flow through the "cold blast main" (14) up to the stoves. This cold blast then enters the stove that has been previously heated and the heat stored in the refractory brick inside the stove is transferred to the "cold blast" to form "hot blast". The hot blast temperature can be from 1600°F to 2300°F depending on the stove design and condition. This heated air then exits the stove into the "hot blast main" (13) which runs up to the furnace. There is a "mixer line" (15) connecting the cold blast main to the hot blast main that is equipped with a valve used to control the blast temperature and keep it constant. The hot blast main enters into a doughnut shaped pipe that encircles the furnace, called the "bustle pipe" (13). From the bustle pipe, the hot blast is directed into the furnace through nozzles called "tuyeres" (30) (pronounced "tweers"). These tuyeres are equally spaced around the circumference of the furnace. There may be fourteen tuyeres on a small blast furnace and forty tuyeres on a large blast furnace. These tuyeres are made of copper and are water cooled since the temperature directly in front of the them may be 3600°F to 4200°F. Oil, tar, natural gas, powdered coal and oxygen can also be injected into the furnace at tuyere level to combine with the coke to release additional energy which is necessary to increase productivity. The molten iron and slag drip past the tuyeres on the way to the furnace hearth which starts immediately below tuyere level.

Around the bottom half of the blast furnace the "casthouse" (1) encloses the bustle pipe, tuyeres and the equipment for "casting" the liquid iron and slag. The opening in the furnace hearth for casting or draining the furnace is called the "iron notch" (22). A large drill mounted on a pivoting base called the "taphole drill" (23) swings up to the iron notch and drills a hole through the refractory clay plug into the liquid iron. Another opening on the furnace called the "cinder notch" (21) is used to draw off slag or iron in emergency situations. Once the taphole is drilled open, liquid iron and slag flow down a deep trench called a "trough" (28). Set across and into the trough is a block of refractory, called a "skimmer", which has a small opening underneath it. The hot metal flows through this skimmer opening, over the "iron dam" and down the "iron runners" (27). Since the slag is less dense than iron, it floats on top of the iron, down the trough, hits the skimmer and is diverted into the "slag runners" (24). The liquid slag flows into "slag pots" (25) or into slag pits (not shown) and the liquid iron flows into refractory lined "ladles" (26) known as torpedo cars or sub cars due to their shape. When the liquids in the furnace are drained down to taphole level, some of the blast from the tuyeres causes the taphole to spit. This signals the end of the cast, so the "mudgun" (29) is swung into the iron notch. The mudgun cylinder, which was previously filled with a refractory clay, is actuated and the cylinder ram pushes clay into the iron notch stopping the flow of liquids. When the cast is complete, the iron ladles are taken to the steel shops for processing into steel and the slag is taken to the slag dump where it is processed into roadfill or railroad ballast. The casthouse is then clean-up and readied for the next cast which may occur in 45 minutes to 2 hours. Modern, larger blast furnaces may have as many as four tapholes and two casthouses. It is important to cast the furnace at the same rate that raw materials are charged and iron/slag produced so liquid levels can be maintained in the hearth and below the tuyeres. Liquid levels above the tuyeres can burn the copper casting and damage the furnace lining.

CONCLUSION

The blast furnace is the first step in producing steel from iron oxides. The first blast furnaces appeared in the 14th Century and produced one ton per day. Blast furnace equipment is in continuous evolution and modern, giant furnaces produce 13,000 tons per day. Even though equipment is improved and higher production rates can be achieved, the processes inside the blast furnace remain the same. Blast furnaces will survive into the 2000 millennium because the larger, efficient furnaces can produce hot metal at costs competitive with other iron making technologies

No comments:

Post a Comment